Medical devices and instruments often use pumps to move fluids or gases, where the choice of pump depends on the specific application and requirements.

Many pumps, like the vacuum vane pump and the magnetic levitation centrifugal pump, are very versatile, with small footprints, and can be used for many applications. Many types of pumps can operate under dual modes, generating either positive pressure or a vacuum, adding to their versatility.

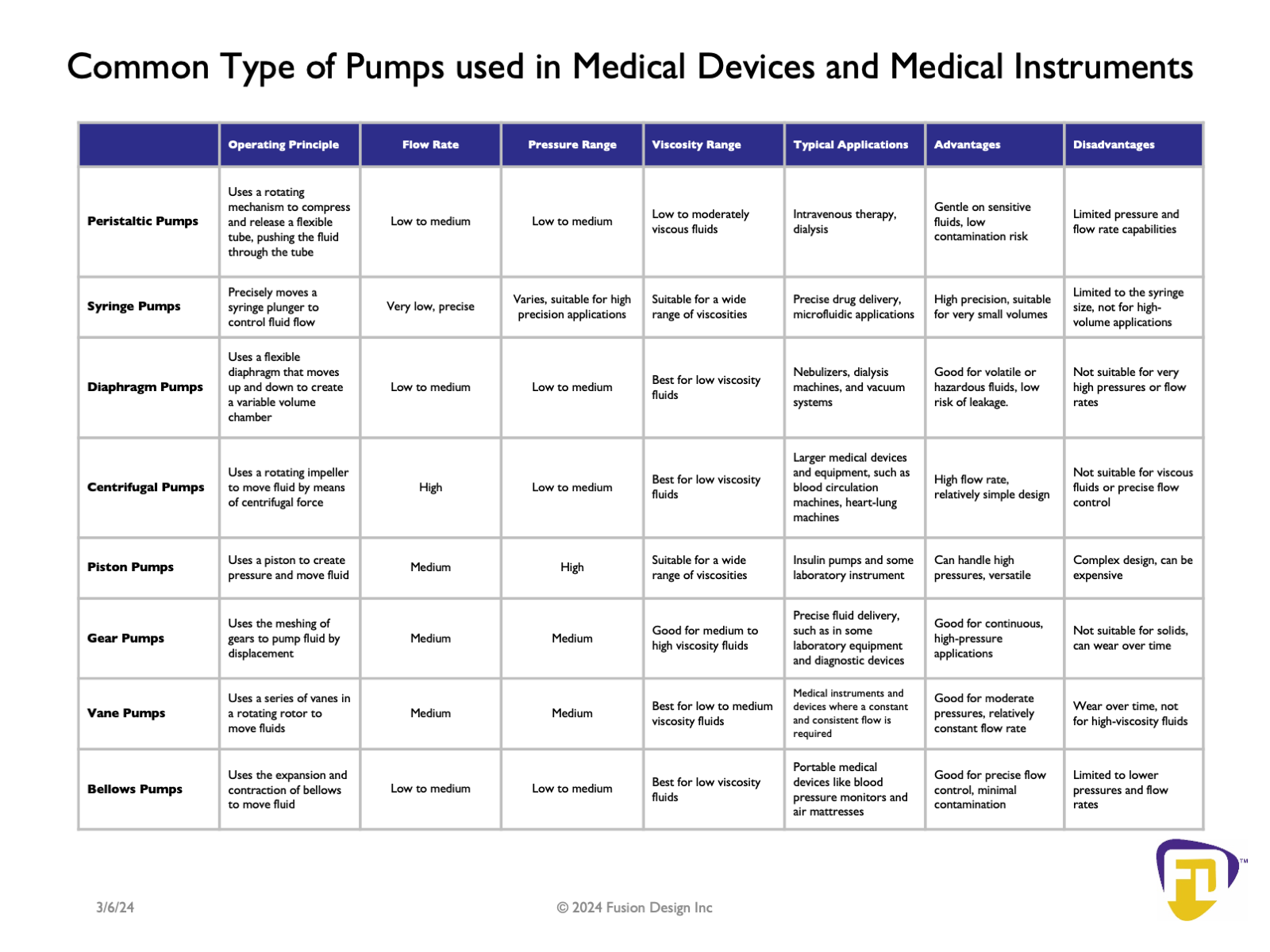

Some of the most common types of pumps used in medical devices and instruments include:

Peristaltic pumps

Peristaltic pumps are commonly used in medical devices like infusion pumps and blood analyzers. They compress and relax flexible tubing to move fluids without direct contact between the pump and the fluid.

This type of pump provides a gentle pumping action, making it suitable for handling delicate fluids or shear-sensitive materials such as biological samples or pharmaceuticals. It also offers excellent accuracy and precision in flow rates. Its self-priming capability allows it to efficiently handle viscous or high-solids content fluids without clogging, reducing maintenance needs. However, peristaltic pumps have limited pressure and flow rate capabilities.

Syringe pumps

Syringe pumps deliver precise amounts of fluid in medical applications. They are commonly employed in drug infusion systems, anesthesia machines, and laboratory equipment.

Their programmability allows for customizable infusion rates, accommodating a range of patients' needs. Moreover, syringe pumps facilitate continuous delivery, ensuring a steady supply of medication or fluids over extended periods, reducing the need for frequent manual interventions.

Diaphragm pumps

Diaphragm pumps use a flexible diaphragm to create a positive or negative pressure to move fluids. They are often used in devices like nebulizers, dialysis machines, and vacuum systems.

Diaphragm pumps offer precise fluid control, ensuring accurate dosing in drug delivery systems and blood analyzers. Their pulsation-free operation benefits sensitive applications like infusion pumps, preventing damage to delicate samples or tissues. They can handle aggressive chemicals and sterilization processes without degradation. Additionally, they are often compact, lightweight, and easy to sterilize, meeting stringent medical hygiene standards. While they can handle moderate pressure and flow rates, they may not be as efficient or effective in situations requiring extremely high pressures or flow rates. Here is an interesting teardown.

Centrifugal pumps

Centrifugal pumps are used in larger medical devices and equipment, such as blood circulation machines, heart-lung machines, and some diagnostic instruments. They generate flow by using a rotating impeller to create a centrifugal force.

One key application is cardiopulmonary bypass (CPB) machines utilized during cardiac surgeries. These pumps ensure continuous blood flow during procedures, maintaining perfusion to vital organs while the heart is temporarily stopped. They draw blood from the patient's body, oxygenate it, remove carbon dioxide, and then return it to the patient's circulatory system. This continuous flow of oxygenated blood ensures that vital organs receive the necessary oxygen and nutrients during the surgical procedure. Their ability to handle continuous flow and compatibility with blood makes them ideal for sustaining vital functions in these critical situations.

Centrifugal pumps provide continuous and smooth flow. They can handle both corrosive and non-corrosive fluids. Centrifugal pumps are not self-priming and must be used in flooded suction applications. These pumps cannot be run dry.

One of the popular centrifugal pumps is the magnetically levitated centrifugal continuous-flow pump.

Piston pumps

Piston pumps are employed in various medical devices, including insulin pumps and some laboratory instruments. They use a reciprocating piston to move fluids in a controlled manner.

Piston pumps provide precise control over fluid delivery, which is crucial for applications like drug infusion and fluid transfer in surgeries. Their ability to handle a wide range of viscosities makes them versatile for various medical fluids. Moreover, piston pumps are durable and reliable, ensuring consistent performance over time. Additionally, they can operate at high pressures, necessary for applications such as angioplasty or anesthesia delivery.

Gear pumps

Gear pumps use interlocking gears to move fluids, providing precise flow rate control. Due to their precision and reliability in fluid handling, gear pumps are extensively used in medical devices, including infusion pumps, dialysis machines, and medical instruments. They are also used in ventilators for gas regulation and drug delivery systems for medication administration. Additionally, gear pumps are used to transfer fluids between different components of laboratory equipment, such as centrifuges and chromatography columns.

Gear Pumps are self-priming and constant-flow pumps when RPM and differential pressure are constant. The construction materials for the gears and seals provide a wide range of fluid compatibility.

Vane pumps

Vane pumps are used in medical instruments and devices where a constant and consistent flow is required. They operate using rotating vanes inside a cylindrical chamber.

Vane pumps can maintain a high level of accuracy in delivering fluids. The vane pumps’ compact size suits space-constrained medical devices, and easy control facilitates precise flow rate adjustments.

One popular vacuum pump is Edwards’ RV3 rotary vane vacuum pump.

Bellows pumps

Bellows pumps, which use flexible bellows to generate air or fluid flow, are often found in portable medical devices like blood pressure monitors and air mattresses.

Bellows pumps provide precise control over fluid flow for drug delivery or infusion systems. They can handle both corrosive and non-corrosive fluids. Their compact size makes them suitable for portable and implantable medical devices.

However, bellows pumps are limited to lower flow rate applications than other pump types and require stringent sterilization procedures.

Summary

The pump type selection depends on the required flow rate, precision, fluid compatibility, size constraints, and other specific application requirements. We choose the appropriate pump type to ensure safe and accurate fluid or gas transport in healthcare settings.