Waterproof enclosures are used in many industries, from oil fields to consumer electronics.

Unfortunately the term “waterproof” tends to be subjective. For your application how “waterproof” is enough?

The “Ingress Protection (IP)” system is an evaluation of electronics housings that gives real meaning to the term “waterproof". It provides real tests that must be passed for different levels. The system has two unrelated numbers following the IP: The first number indicates how dustproof an enclosure is and the second indicates how waterproof it is. A good table of the IP ratings can be found at https://en.wikipedia.org/wiki/IP_Code.

For a waterproof enclosure design, we check all of the items in this checklist and more. Some of the items in the list are general guidelines and we often need to use engineering judgment on the trade-off between the size, cost, and manufacturability of the enclosure.

Sealing material

Check that the sealing material conforms easily to the flange surfaces

Review possible variations in the effects of temperature and pressure

Verify the elasticity of the material

Review the deterioration over time (i.e. chemicals, cracking, creep)

Check for the risk for dirt, water, and other contaminants

Confirm RF sealing AND water sealing as needed

Verify sufficient clearance for material compression

Review compression force vs sealing capacity

Verify tolerance allowance and compliance

Review premade gasket vs dispensed gasket

Check for the possibility of outgassing

Confirm the availability of components

Research the cost

Review manufacturability

Housing material and configuration

Review type of housing material

Verify environmental resistance (temperature, ice, rain, wind, dust, sun)

Review shape stiffness vs number of fasteners vs locations for proper compression

Confirm Mfr compression requirements including tolerance

Review face seal vs wiping seal vs other type of seal

Check seal designed for water impact and deflection

Review pressure variation management

Check deterioration over time (creep, cracking, other)

Review planer vs stepped seal

Verify absolute minimum seal count and length

Research cost

Review manufacturability

Type of clamping / compression

Verify sufficient clamping by bolts, screws or other

Check what is the clamping force for proper sealing

Review flange distortion vs seal tolerance

Confirm surface finish of flange required

Review risk for dirt, water, and other contaminants ingress

Drop test impact resistant

Verify that the Circular seal diameter matches mfr requirements

Ease of assembly / disassembly / reassembly

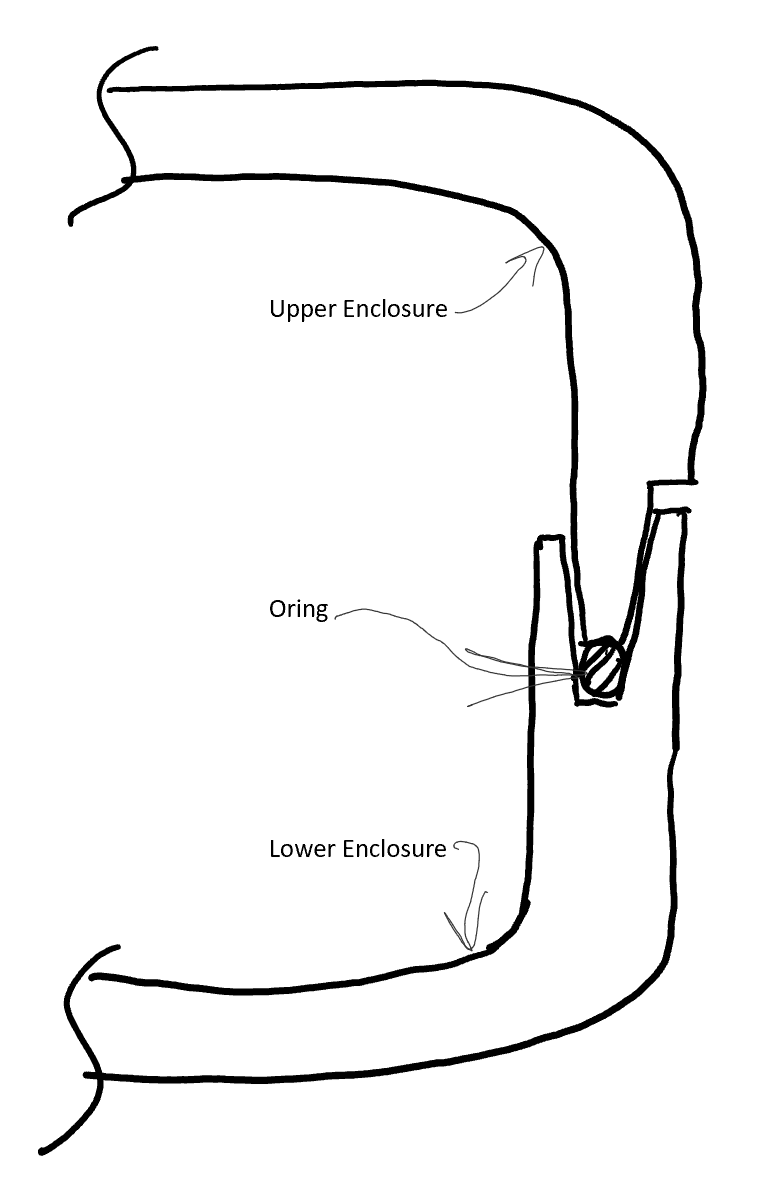

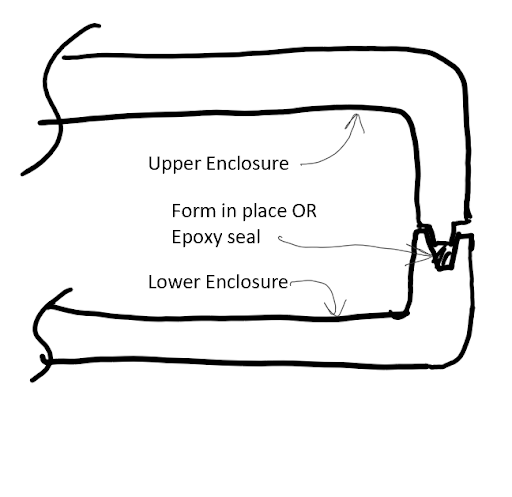

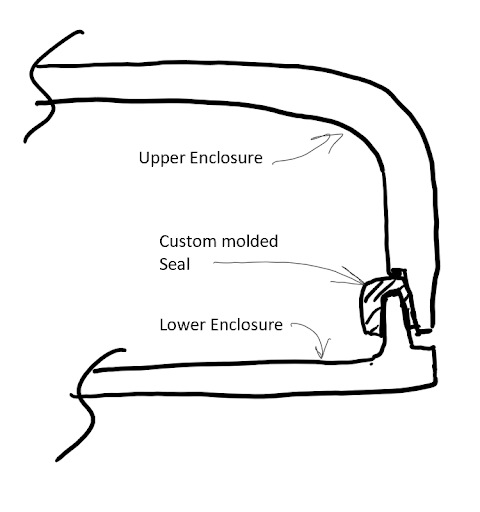

Some of my favorite seal designs for clamshell enclosures

Additional Resources

WESTPAK's "Top Failures Observed During Gross Leak Detection and Seal Strength Testing of Medical Device Packaging" webinar