Since 1990 we have been helping large companies and startups overcome their challenges on the journey from concept to product end of life. Our design process fits into an overall product development process that balances engineering trade-offs to develop a system, or component, to meet the desired needs.

At Fusion Design, we do industrial design and mechanical engineering and our process always starts with the needs and requirements of the user. We believe that a successful project must meet or exceed these needs and requirements. We orient our efforts within six phases of development.

Note that the first three phases are Industrial Design centric. The next three phases are Mechanical Design centric. Industrial designers are joined by a few mechanical engineers in the first three phases to insure manufacturability. Mechanical Engineers are joined by a few Industrial Designers in the second three phases to insure retention of design intent.

Strategy: Always Start With User Needs

To understand user requirements fully, we do client interviews, brainstorming and competitive research. We look at interconnectivity - how do products and features work together? How will the device be used? We also look at image attributes. What should the device look like? How should it work? What are the paradigms that are in the industry now? What are your competitors doing, and where do you fit within that? How do you position yourself?

We do user research, competitive research, market trend research and ergonomic research. Sometimes this requires building a mockup and watching how people use it. We worry about what's comfortable. How much can people lift? At seating positions, what's the eye line? How much weight can people carry? User profiles are a powerful tool for developing and testing ideas and strategies.

After our research efforts, we might build models that test what the users will want, and then watch them in use. Often users' reactions and behavior tell you more about what is needed than their words. So our motto is to "watch behavior."

Product development example of eye surgery machine control panel

In one classic example, for the design of an eye surgery machine control panel, the user/doctor had been a fighter pilot and had changed careers to become an eye surgeon. We had built a push button panel mock up, where you push the buttons to get things to work; more light, less light, focus this, focus that, move patient up, down, more energy, etc.

He saw that and he said, “You know, I don't like this. I like knobs.” But before that, every doctor except him had said, “Oh, I love these push buttons.” The ex-fighter pilot said that he preferred knobs specific to each functional aspect. “As I’m looking through the microscope, I can reach over here, turn the brightness up or down and always know where that is. I don't even have to look. This control is power and this is brightness. All are oriented based on position.” This was important because the doctor is in a dark room when he's doing eye surgery. We mocked up what he requested, darkened the room, and let him and several other doctors try it and we learned a lot from that. Every doctor agreed. The machine that we built has knobs, not buttons, even though the original paradigm was buttons. That's why we do research.

Conceptualization

We start by sketching and brainstorming and quickly the concept begins to take shape. We start to formally define the mechanical envelope and the product/user interaction and we begin testing sketch and ergonomic mockups.

Conceptualization can include all of these elements:

Brainstorming

Mechanical Concepts

Mechanical Envelope Definition

Product/ User Interaction

Concept Sketching

Exploratory Sketching

Sketch Mockups

Ergonomic Mockups

Refinement

Scale Mockups

2D Renderings

Sketch Rendering

3D CAD Rendering

User interface Concepts

Storyboarding

After conceptualization comes the refinement stage that can range from mini or full scale mock ups to 2D&3D CAD renderings. We also use storyboards to validate our initial user interface concepts.

Definition

At this point we'll do the definition. Color, texture and finish are defined with 3D models. These are what we call “skin” models since they only represent the outer surfaces of the shapes. All the mechanical and manufacturing details have been planned but not yet integrated. That is one of the primary tasks of the Mechanical Design effort.

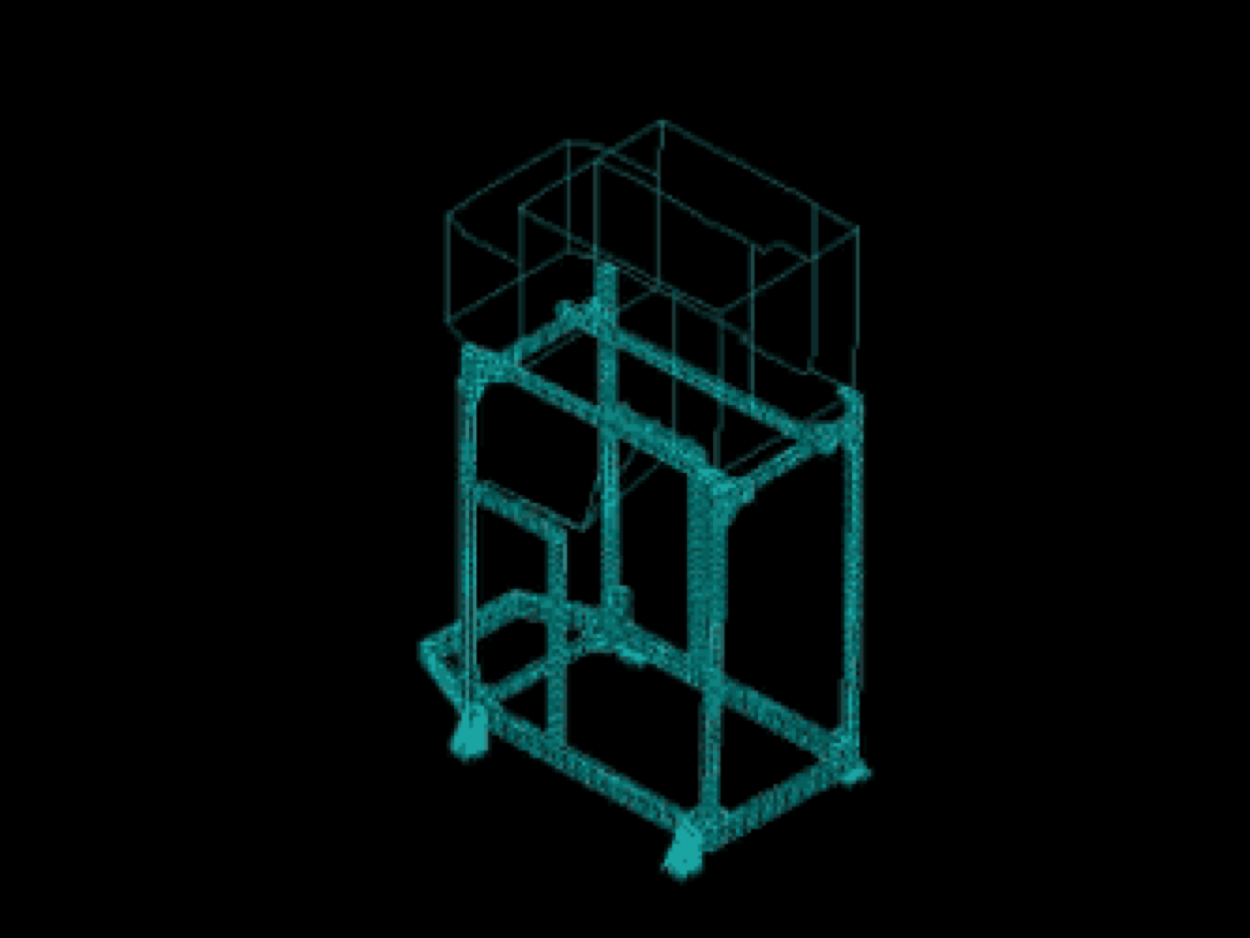

Mechanical Design

Using SolidWorks, we build full 3D models (assemblies and components). Working with the electric team, we develop the circuit board layouts, define connector positions, mounting points, switches, fans and power supplies. DFM (Design for Manufacturability) is a huge part of this effort since great products are only possible if you can make them cost effectively. We integrate known components like motors, switches, LED and batteries. These often involve liaison work with many component suppliers to insure function, cost and availability.

Design Validation

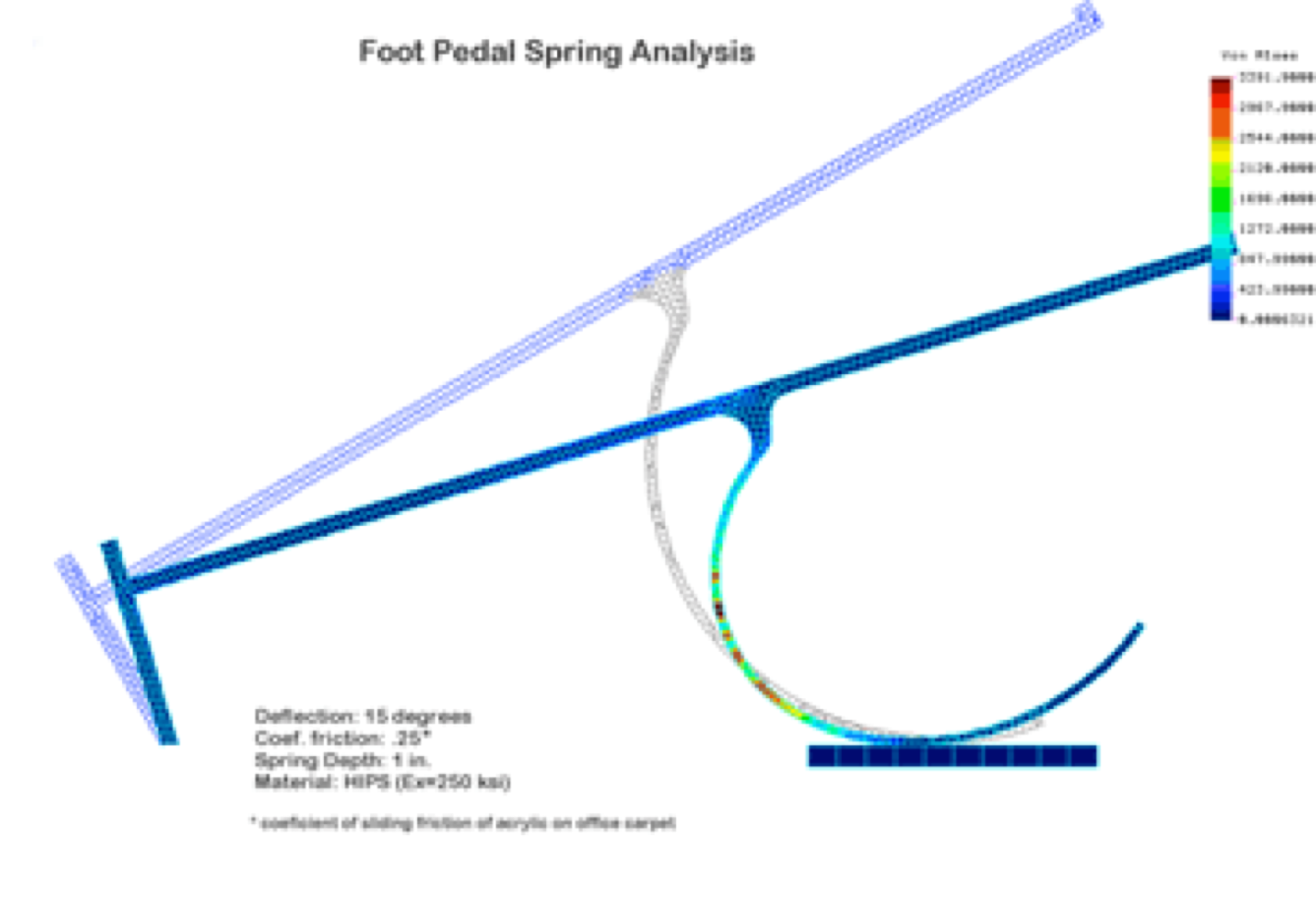

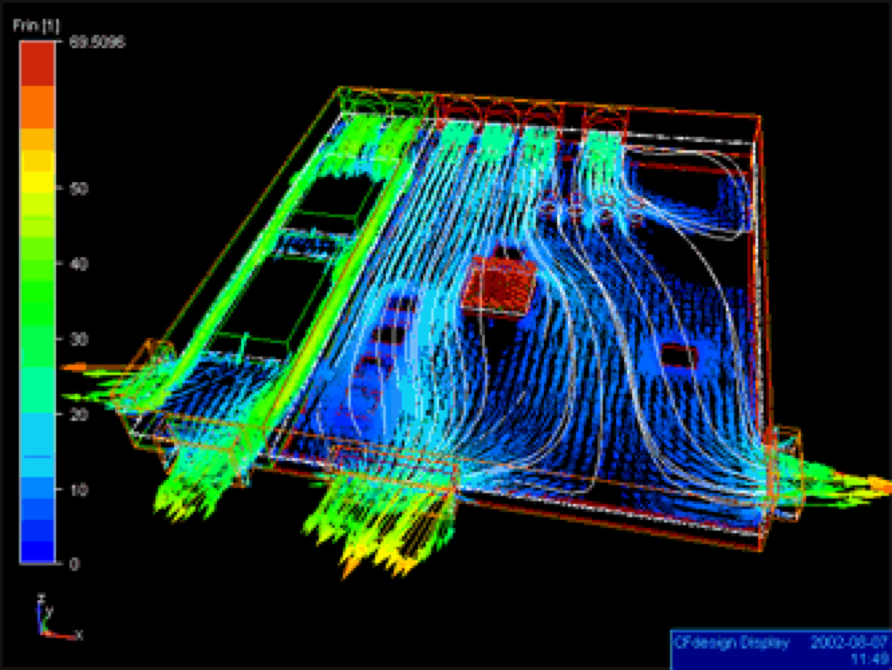

We do validation of the design including thermal analysis, airflow analysis, fluid dynamics analysis, and structural analysis. This often involves both computer models and physical mock ups. We quickly and accurately optimize the design for system performance objectives:

Limit a critical temperature, stress, or vibration response.

Minimize weight, cost, or defects,

Maximize performance, reliability, throughput, reconfigurability, agility, or design robustness.

Common types of validation:

Structural Analysis

Thermal Simulation

Vibration Analysis

Fluid Dynamics Analysis

Mechanism Design

Combined Analysis

Mockup Testing

Prototyping

Rapid 3D Printed Prototypes

Machined, Cast, Sheet Metal Prototype Components

Short-run Prototype Assemblies

Using our in-house 3D printers, our internal fabrication shop as well as outside vendors, we do a great deal of prototyping. When needed we have the resources to build short runs prototypes and explorative assemblies, thus giving confidence in the final design and ensuring a successful manufacturable product.